7-04-2001

revised 9-21-2004 (found cause of intermittent blower)

revised 3-5-2007 (updated layout to newer format)

My blower motor was running intermittently. The IHKA & "sword" checked out o.k. so I concluded the motor itself was the problem, probably brushes. They were indeed worn & the commutator of the armature was badly grooved & worn down about .040" & very dirty so I polished the commutator & replaced the brushes.

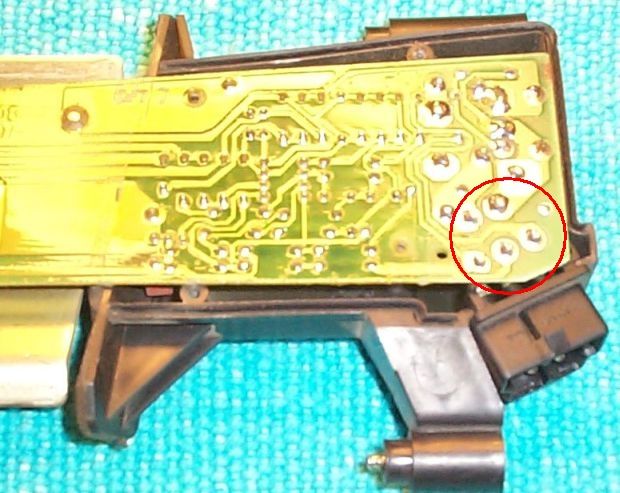

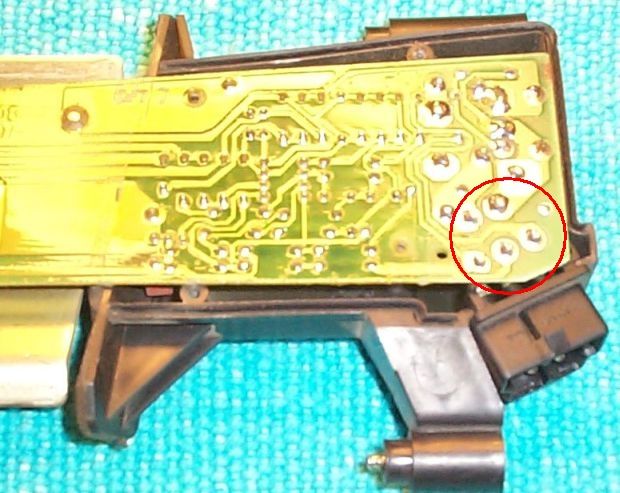

Update: I have since found the real cause of the intermittent blower to be in the sword. The connections under the "handle" where the 5-pin connector socket attaches to the pc board had cracked solder joints. I re-flowed new solder on all 5 joints and it's been working perfectly now for several years:

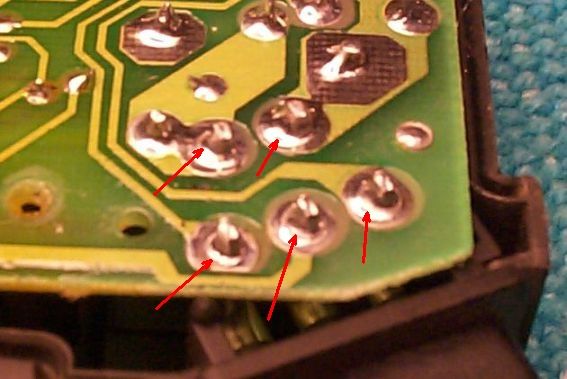

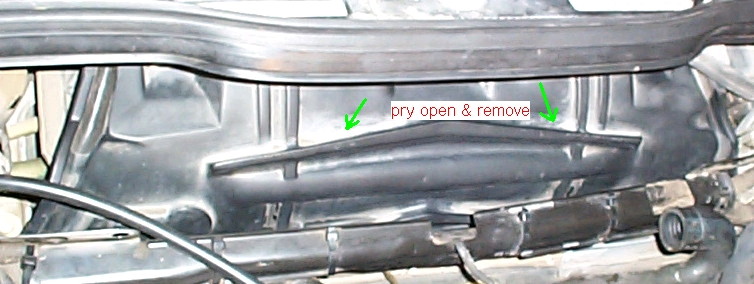

To remove the blower, remove the coolant expansion tank & the bulkhead panel:

The panel is fastened with five screws, one ea. in the four corners & one along the bottom middle. The top edge of the hood weather strip lifts off. There is a brake line tight up against the bottom edge of the panel but it can stay put, the panel will slide straight up so the brake line isn't a problem. Bentleys gives a good description on page 640-2 but his instructions on removing the blower are skimpy. With the panel removed, there is a second flimsy inner dust cover panel held down with just caulk on the underside. It prys out easily from the top:

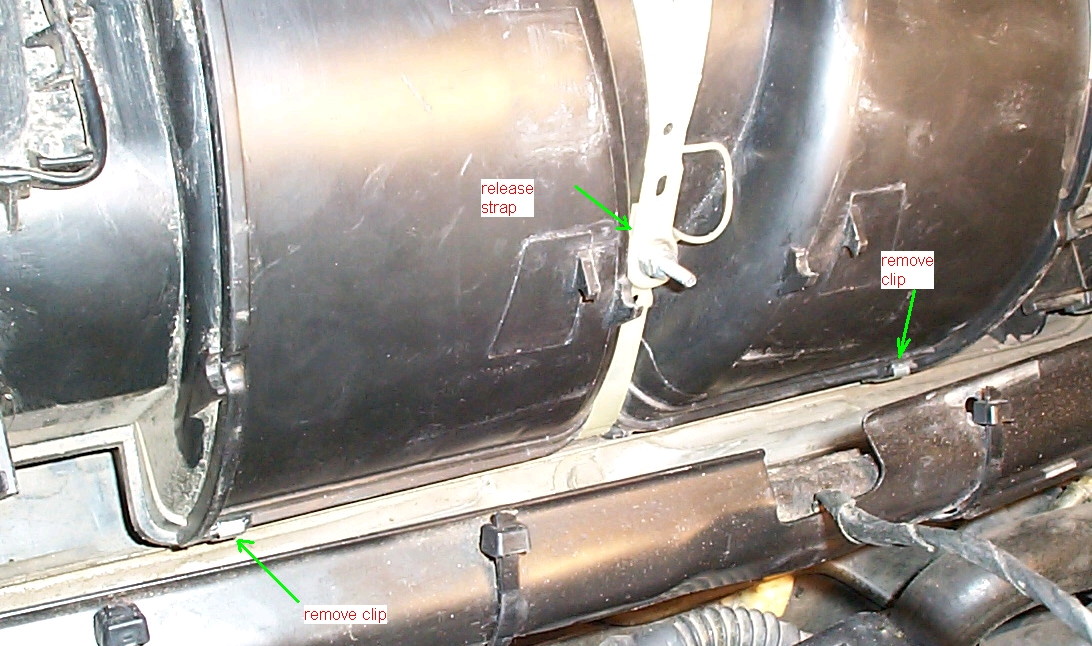

Next, undo the center strap & remove the two clips on the bottom of the center impeller housing:

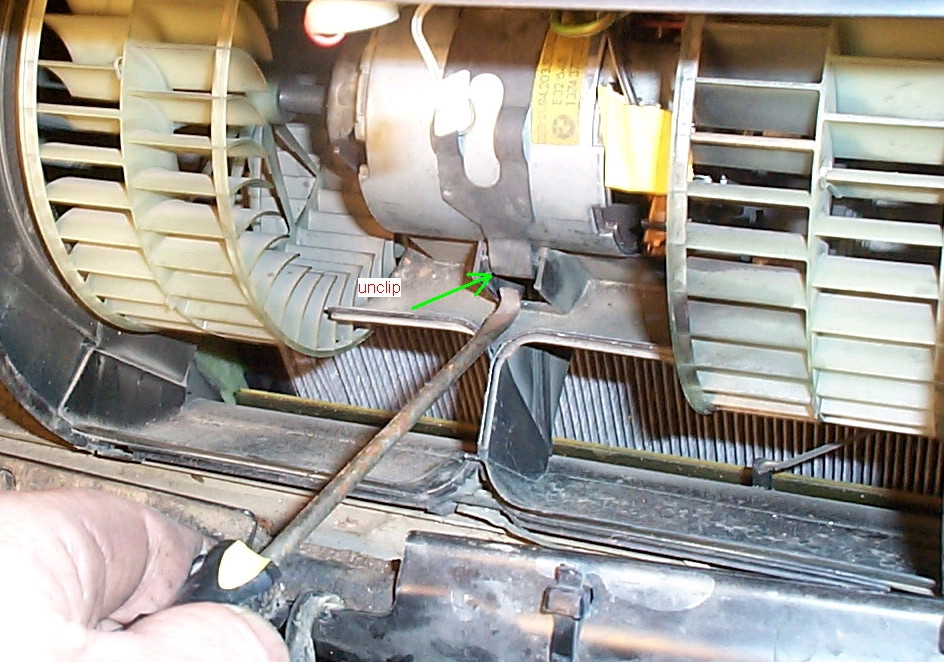

Remove this cover & the blower motor is now exposed. Unclip the metal strap on the center of the motor case:

Note the top edge of the "sword" & microfilter in the background.

The blower impellers are a struggle to pry out past the wire harness, but the harness will flex out of the way enough to get it out intact. The rubber hood seal will lift off to give a little more clearance.

I polished the armature commutator on a lathe with 600 grit wet-or-dry with WD-40 as a lubricant & cleaned with contact lube/cleaner. Mine was badly worn:

I suspect the brush wire is crimped into the solder socket so I snipped it mid-way to remove the brushes, I spliced them back together with a small brass crimp sleeve & soldered. Too much solder will wick & make the lead wire too stiff to flex easily. The closest I could come to a matching brush was from NAPA for an 86-94 Nissan/Hitachi alternator, part no. E395. It takes two sets at $5.95 each. I had to double them up to equal the size of the Bosch brushes. They'll wear in unison so I see no problem doubling them. The Bosch is .312" x .390" x ? long. The Nissan brushes are .195" x .310" x .700" long so fit fine:

I matched the curvature by fashioning a drum sander with 180 grit on a PVC pipe the same diameter as the commutator, chucked in the lathe with the brushes chucked in the toolholder. It sacrifices many miles of natural wear but mates the contour properly from the beginning. The folded brass clips on the brush holder on the motor will probably snap off if I have to repair it a second time, & with the amount of wear on the commutator, I'll probably just buy a new Behr blower motor next time. They go for about $125 at J.A.C., Zygmunt's, etc. I tried to get a little lube into the bearings but they're sealed & probably didn't do any good.

The hardest part of the whole job is getting the lower bulkhead cover screw back in behind the brake booster. I cannot speak for how easy/difficult it is to remove the blower motor on a 740 or 750. Things might be much more congested against the firewall on those. From Bentley's photos, it looks like a 750 should be easy but can't be so sure about a 740.

gale, 92 735i